lead shot hardness test|cast lead hardness chart : companies Both the Winchester AA and Remington STS shells were more consistent, with the Remington STS loads having the highest efficiency patterns on average. Unsurprisingly, STS lead #7-1/2 shot, which won in the Micro . Table 7 from the Guideline for Disinfection and Sterilization in Healthcare Facilities (2008).

{plog:ftitle_list}

$200.00

Both the Winchester AA and Remington STS shells were more consistent, with the Remington STS loads having the highest efficiency patterns on average. Unsurprisingly, STS lead #7-1/2 shot, which won in the Micro . Lee Lead Hardness Test Kit will determine the exact Brinnell Number of an alloy in a simple 6 step process. Included is the Lee Pocket Micro Scope Lee Lead Hardness Test Kit will determine the exact Brinnell Number of an alloy in a simple 6 step process. Included is the Lee Pocket Micro ScopeLee Lead Hardness Test Kit will determine the exact Brinnell Number of an alloy in a simple 6 step process. Included is the Lee Pocket Micro Scope.

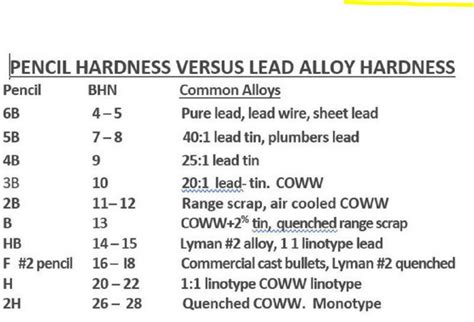

The lee hardness tester will only work on a lead sample that is large enough to perform the test. If you melt down the shot to create an ingot to test, you have completely changed the hardness. You heated above 610 deg and then cooled. I have one really good recommendation for a hardness tester that provides the most versatile testing of lead alloys. It can be used with cast bullets, ingots, slabs, etc. It gives a BHN hardness result, which can be directly referred to. There's a way to do a hardness test with a drill press, a ball bearing, calipers and a bathroom scale. Basically, you put the lead sample on the scale, press the ball bearing into the lead with the drill press, measure the indent with the calipers and do the math. Test Hardness of Pure Lead. The hardness tester will only be accurate over the hardness range listed in the instructions. The indenter ball diameter determines the range over which the tester is accurate.

If you are not concerned about the brinell hardness nrs, you could find out which is the hardest/softest by doing a simple test. If you find something fairly heavy, ie a piece or rail scrap. hold the thing over a piece of shot at a specific distance and drop it. The test shows the hardness of the shot, not the actual antimony content. The antimony content is an estimated "antimony equivalent" based on the hardness of the shot. Federal is using similar language in their new reloadable Gold Medal Grand shells saying, "We use a special lead alloy that provides the hardness of 5 percent antimony lead." Both the Winchester AA and Remington STS shells were more consistent, with the Remington STS loads having the highest efficiency patterns on average. Unsurprisingly, STS lead #7-1/2 shot, which won in the Micro Vickers Hardness testing also produced the best patterns.The Lee Lead Hardness Testing Kit will determine the exact Brinnell Hardness Number of an alloy in a simple six step process. The process involves pressing a hardened steel indenter ball into the bullet through the use of a standard single stage press.

Lee Lead Hardness Test Kit will determine the exact Brinnell Number of an alloy in a simple 6 step process. Included is the Lee Pocket Micro ScopeLee Lead Hardness Test Kit will determine the exact Brinnell Number of an alloy in a simple 6 step process. Included is the Lee Pocket Micro Scope.

The lee hardness tester will only work on a lead sample that is large enough to perform the test. If you melt down the shot to create an ingot to test, you have completely changed the hardness. You heated above 610 deg and then cooled. I have one really good recommendation for a hardness tester that provides the most versatile testing of lead alloys. It can be used with cast bullets, ingots, slabs, etc. It gives a BHN hardness result, which can be directly referred to. There's a way to do a hardness test with a drill press, a ball bearing, calipers and a bathroom scale. Basically, you put the lead sample on the scale, press the ball bearing into the lead with the drill press, measure the indent with the calipers and do the math. Test Hardness of Pure Lead. The hardness tester will only be accurate over the hardness range listed in the instructions. The indenter ball diameter determines the range over which the tester is accurate.

If you are not concerned about the brinell hardness nrs, you could find out which is the hardest/softest by doing a simple test. If you find something fairly heavy, ie a piece or rail scrap. hold the thing over a piece of shot at a specific distance and drop it. The test shows the hardness of the shot, not the actual antimony content. The antimony content is an estimated "antimony equivalent" based on the hardness of the shot. Federal is using similar language in their new reloadable Gold Medal Grand shells saying, "We use a special lead alloy that provides the hardness of 5 percent antimony lead." Both the Winchester AA and Remington STS shells were more consistent, with the Remington STS loads having the highest efficiency patterns on average. Unsurprisingly, STS lead #7-1/2 shot, which won in the Micro Vickers Hardness testing also produced the best patterns.

acl tear test video

lead hardness tester reviews

lead hardness test chart

lead hardness calculator

It is very important to ensure that all of the trapped air is removed from the autoclave before activation, as trapped air is a very poor medium for achieving sterility. Steam at 134 °C (273 °F) can achieve a desired level of sterility in three minutes, while achieving the same level of sterility in hot air requires two hours at 160 °C (320 °F). Methods of air removal include: Downward displacement (or gravity-type): As steam enters the chamber, it fills the upper areas f.

lead shot hardness test|cast lead hardness chart